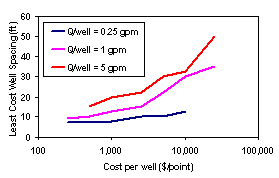

Field tests have shown that EOS® can be distributed large distances in the subsurface from just a few injection points. However, drilling costs are only one part of the total project cost. Using a larger well spacing can increase the total cost by increasing the time (i.e. labor cost) for injection.

The graph below illustrates the effect of drilling costs and injection well-flow rates on the least cost well spacing. When injection rates and drilling costs are low, it is actually less expensive to use closely spaced wells. However, as drilling costs and/or feasible injection rates increase, larger well spacings become more cost effective. For large projects, it is useful to generate cost estimates for several different well spacings to find the least cost alternative. A site-specific analysis should consider the available water supply, access restrictions, continuous versus intermittent injection, labor and drilling costs, etc.